What are some common materials used to make awls? Awls typically use high-carbon steel for sharp, durable blades and wood or plastic for comfy handles. These materials ensure strength and control.

As a 45-year-old crafter in Albuquerque with 20 years of experience, I’ve used many awls, from bone to steel, to pierce leather, wood, and fabric without tearing.

Awls vary by craft—leatherworking, woodworking, or sewing—and their materials reflect their purpose, from ancient flint to modern composites. A typical awl is a 3-6 inch tool with a pointed spike and ergonomic handle.

Table of Contents

What Are Some Common Materials Used to Make Awls?

Awl materials define their performance. The blade needs to stay sharp and tough; the handle must feel good for long sessions. Below, I break down blade, handle, and other components, plus maintenance and safety tips.

All Awl Blade Materials

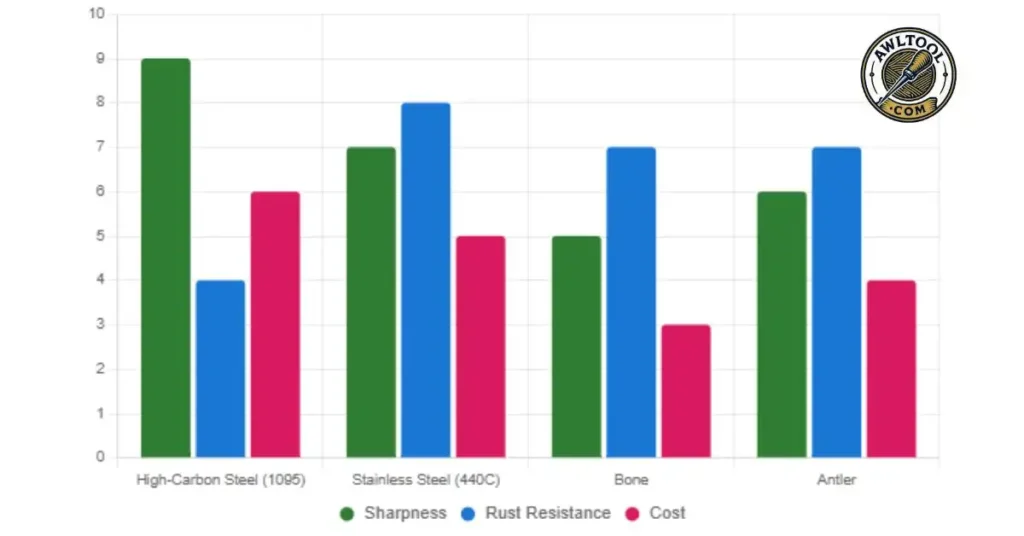

Comparison Table: Blade Materials

| Material | Hardness | Durability | Rust Resistance | Best Use |

|---|---|---|---|---|

| High-Carbon Steel | High | High | Low | Leatherwork, Woodworking |

| Stainless Steel | Medium | High | High | Marine, Humid Environments |

| High-Speed Steel | Very High | High | Medium | Heavy-Duty Professional Use |

| Bone | Low | Low | High | Traditional Crafts |

| Antler | Medium | Medium | High | Historical Reenactments |

| Flint | Medium | Low | High | Ancient Craft Replications |

Recommendation: For leatherwork, try the WUTA Stitching Awl with a high-carbon steel blade. For woodworking, a high-speed steel awl like the Stanley Scratch Awl works best.

The sharp blade of an awl needs to stay tough and hold an edge. Here are the most common materials:

- High-Carbon Steel: Modern awls, especially for leatherworking, often use high-carbon steel like 1095 spring steel. It’s hardened for strength and sharpens easily. I rely on this for my C.S. Osborne awls when stitching belts.

- Stainless Steel: Grades like 440C resist rust and are heat-treatable, ideal for humid environments. I use these for outdoor projects in New Mexico’s dry climate.

- High-Speed Steel: Used in premium awls, it holds an edge longer for heavy tasks like woodworking. It’s pricier but worth it for pros.

- Repurposed Metal: DIY crafters get creative with:

- Sharpened Nails: Large nails ground to a point work for budget awls.

- Old Screwdrivers: Ground-down tips make sturdy blades.

- Thick Music Wire: Strong and flexible for small-scale piercing.

- Bone: Historically, Native Americans shaped deer or buffalo bones into sharp points for sewing hides. These are lightweight but less durable than steel.

- Antler: Used in traditional awls, antler blades are tough but wear faster than metal.

- Flint: Ancient awls used knapped flint for piercing. It’s sharp but chips easily, as I learned recreating one for a local history exhibit.

The choice depends on the task. Steel blades excel for modern leatherwork or woodworking, while bone or flint suits traditional or experimental projects. What Are Some Popular Awl Brands?

Common Awl Handle Materials

| Material | Durability | Comfort | Cost | Best Use | Pros | Cons |

|---|---|---|---|---|---|---|

| Walnut | High | High | Moderate | Leatherwork | Sturdy, absorbent | Needs care |

| Maple | High | High | Moderate | Bookbinding | Light, smooth | Can crack |

| Hickory | Very High | High | Moderate | Woodworking | Tough, durable | Heavier |

| Olive Wood | High | High | High | Custom awls | Beautiful grain | Expensive |

| Plastic | High | Medium | Low | Beginner use | Affordable | Slippery |

| Antler | Medium | High | Moderate | Traditional | Rustic, grippy | Wears fast |

| Bone | Low | Medium | Low | Historical | Lightweight | Splinters |

| G10 | Very High | High | High | Professional | Tough, grippy | Costly |

The handle ensures control and comfort during long crafting sessions. Here are the top options:

- Wood: A favorite for its natural feel, wood is durable and easy to shape. Common types include:

- Walnut: Rich and sturdy, great for heavy leatherwork.

- Maple: Smooth and lightweight, ideal for precise bookbinding.

- Olive Wood: Beautiful grain, perfect for custom awls.

- Hickory: Tough for woodworking tasks. I carved a hickory handle for my first awl at a Santa Fe market—it’s still my go-to for long sessions.

- Plastic: Modern mass-produced awls use molded plastic for affordability and durability. It resists cracking but can feel slippery compared to wood.

- Antler: Traditional and rustic, antler handles from deer or elk offer a solid grip. I craft these from local sheds for a New Mexico touch.

- Bone: Used in historical awls, bone handles are lightweight and often carved from the same piece as the blade in ancient designs.

- Composite (G10): A modern synthetic, G10 is tough and grippy, used in high-end awls for pros.

Wood and antler feel best for long projects, while plastic suits beginners on a budget.

Other Components

Some awls have extra parts for strength or function:

- Ferrules: A metal ring, usually brass, copper, or stainless steel, secures the blade to the handle. It prevents wood handles from splitting under pressure. I always check for a tight ferrule on my leather awls—it saves tools from breaking mid-project.

- Stitching Awl Needles: These have a hole like a sewing needle, made from durable steel for threading waxed thread through leather or fabric. The Speedy Stitcher’s steel needles are a staple in my shop.

- Striking Surface: Some awls, like those for heavy leatherwork, have a steel disc on the handle end for hammering without damage.

Why Material Choice Matters

The right materials match the task. High-carbon steel blades cut clean holes in leather without bending. Wood handles reduce hand strain during hours of bookbinding.

Bone or antler adds cultural value for traditional crafts. For woodworking, a steel blade with a hickory handle offers precision and comfort. Choose based on your project’s needs and how long you’ll work.

Maintenance and Care for Awl Materials

Keeping awls in top shape extends their life:

- High-Carbon Steel: Sharpen with a fine whetstone and oil weekly to prevent rust. I use mineral oil after every leatherworking session.

- Stainless Steel: Wipe clean and sharpen less often; avoid abrasive stones to maintain the finish.

- Bone/Flint: Store dry to prevent cracking or chipping. Use gloves to avoid cuts from flint.

- Wood Handles: Condition with linseed oil monthly to prevent drying. My hickory handle stays smooth with regular care.

- Plastic/G10: Clean with soap and water; no special maintenance needed.

- Antler: Polish lightly to maintain grip; avoid soaking to prevent softening.

Check out our guide – How to Sharpen an Awl: 6 Step-by-Step Guide

Safety Tips for Handling Awl Materials

Awls are sharp, so safety matters:

- Steel Blades: Wear gloves when sharpening to avoid cuts. Store in a sheath to protect the tip.

- Flint/Bone: Handle carefully; flint can chip unexpectedly, and bone may splinter. I learned this crafting a flint awl—gloves saved my fingers.

- Wood/Plastic Handles: Ensure a firm grip to prevent slipping during piercing.

Modern Innovations in Awl Materials

Modern awls embrace new materials. Carbon fiber handles are lightweight and tough, ideal for pros. Recycled steel blades appeal to eco-conscious crafters. 3D-printed components, like custom handles, are emerging for bespoke tools. These innovations enhance durability and comfort, keeping awls relevant. I’m excited to try a carbon fiber-handled awl for my next project.

Historical and Cultural Awls

How Native Americans made awls from bone and flint? They shaped deer bones or flint into points for sewing hides. Antler handles gave a firm grip. These tools helped make clothes and tents.

Ancient awls started with copper 6,500 years ago in Israel. Bronze came in the Bronze Age for better precision. Iron followed in Roman times.

Historically, awls used bone tools, flint awls, or metal. Native American awls from buffalo bones were versatile. I admire how they turned local resources into effective tools—much like my early experiments with mesquite wood handles.

endoverendantiques: Point taken. An old bone tool I found this weekend.

Uses and Applications

Which awl is best for woodworking, sewing, or leatherwork? For woodworking, choose a steel-blade scratch awl to mark wood without splitting. Sewing needs a fine steel or bone awl for fabric holes. Leatherwork calls for diamond steel awls to punch tough hides.

Native Americans used bone awls for hide sewing and basket weaving. Today, awls mark, pierce, and start holes.

For recommendations: High-carbon steel for leather awls like the WUTA model—great for belts. Wood handles work best for long woodworking sessions.

FAQs: What Material is the Awl Made Of? About Awls and Their Materials

What Types of Steel Are Used for Modern Awl Blades?

High-carbon steel, 440C stainless steel, high-speed steel, and premium M390 for durability, sharpness, and rust resistance in leatherworking and woodworking.

What Other Materials Are Used for Awl Handles?

Antler, G10 composite, cork, bone, besides wood and plastic, for sturdy, comfortable grips tailored to traditional or modern crafting needs.

What Is the Main Purpose of an Awl?

To pierce or mark materials like leather, wood, or fabric precisely, ensuring clean holes for stitching or guiding cuts without tearing. Learn More.

What Safety Tips Should I Follow with Awl Materials?

Wear gloves with steel or flint blades to avoid cuts. Store in sheaths. Condition wood handles to prevent cracking. Secure grips to avoid slips.

How Do I Choose Awl Materials for My Project?

Choose high-carbon steel for leather or wood, stainless for wet environments. Wood or antler handles suit long sessions; plastic for budget-friendly options.

Are Bone Awls Still Used Today?

Yes, bone awls are used in traditional crafts or reenactments. They’re lightweight but less durable than steel, ideal for historical projects or soft materials.

Are There Different Types of Awls?

Yes, woodworking (scratch, brad), sewing, leather, bookbinding, and harness awls, each tailored for specific materials and tasks. Check this out: 18 Types of Awls.

What Does an Awl Look Like?

A slender, 3-6 inch tool with a sharp metal or bone spike and a wood, plastic, or antler handle for piercing.

What Types of Steel Are Best for Awl Blades and Why?

High-carbon steels (1095, 52100) offer sharpness and toughness for leatherwork. Stainless 440C resists rust for wet tasks. Tool steels (D2, O1) ensure durability for precision.

Conclusion

What material is the awl made of? From bone and flint in history to high-carbon steel and wood today, awls adapt for better use. This evolution makes them reliable for crafts.

As a 45-year-old crafter in Albuquerque, I’ve seen how the right materials boost your work. Pick steel for durability in modern tasks. Join our community for more tips.

What material changed your crafting game? Share below!

Hi, I’m Nicholas N. Goforth, a New Mexico crafter with 20 years of experience in leatherworking, woodworking, and bookbinding.

Inspired by a Santa Fe market, I turned my passion into AwlTool.com, launched in 2025, to share tutorials and handcrafted goods.

Join the conversation on Instagram and Facebook: Share your favorite marking or drilling tools and tag us to get featured!